Solutions

Tailored thermal protection

TMC Sensortechnik GmbH not only offers some of the world’s most innovative thermal protection products. TMC also delivers comprehensive solutions. Challenge us! We develop tailor-made solutions for your specific thermal protection: from the first design sketch, through 3D modeling that integrates seamlessly into your own 3D models, all the way to global permits. Everything from a single source – backed by many years of expertise.

Best Practices

Our thermal solutions are tailored, smart, and resource-efficient.

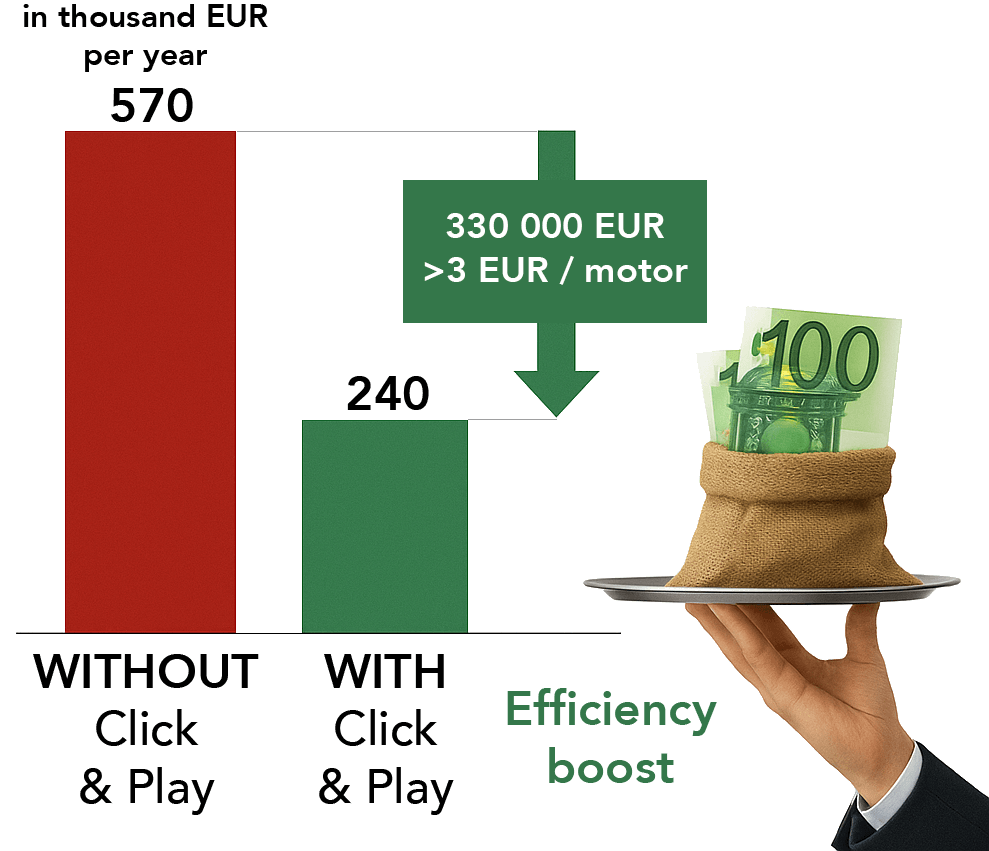

Saving on assembly costs

How can the high assembly costs in electric engine manufacturing be drastically reduced? Our answer: “Click & Play”! With the use of our TMC MR 2nd generation and the automated assembly it enables, costs have been reduced by €0.5 million per year.

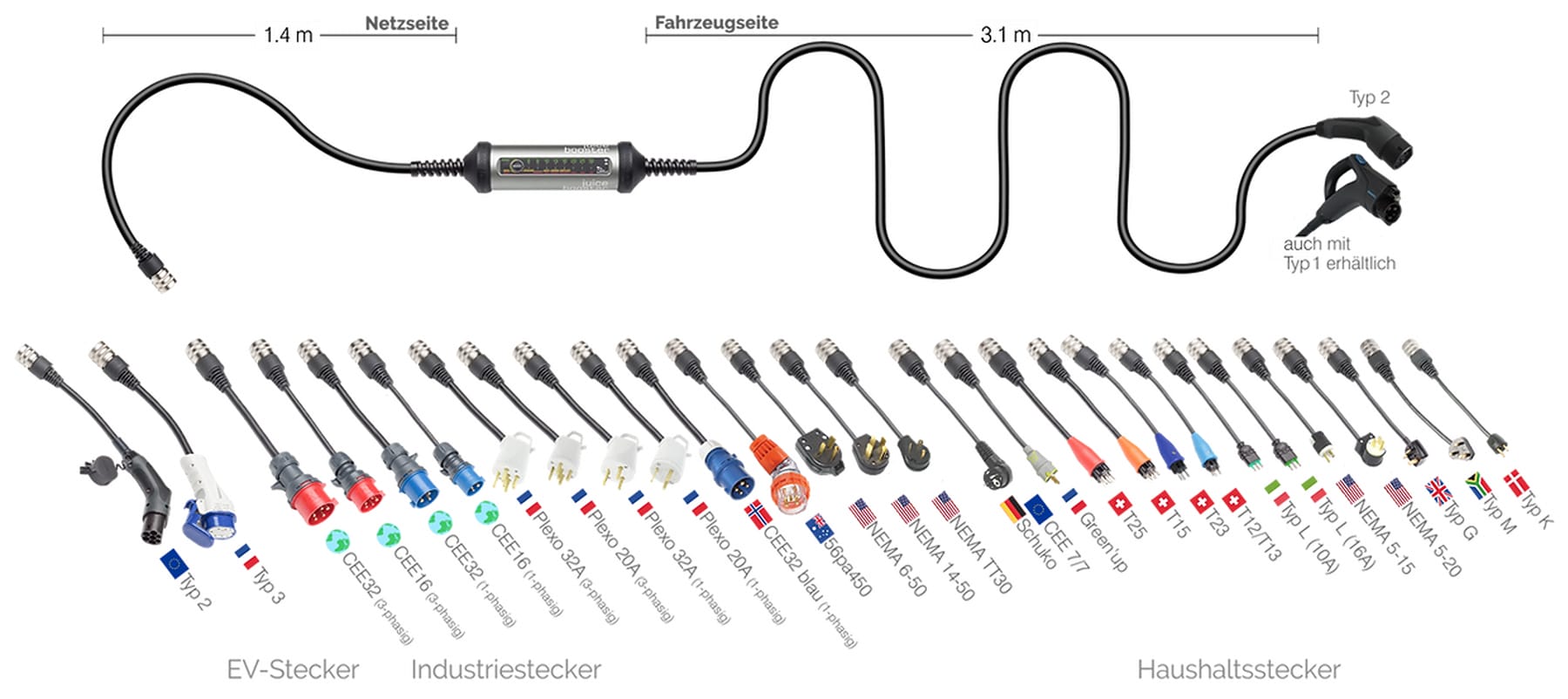

Reliable thermal protection for EV charging systems

How can power plugs of the charging infrastructure for electric cars be protected against overheating?

Our answer: the TMC N series, which makes the Juice Booster a reliable companion for e-mobility. Now also with Pt and PTC technology!

The following product video from Juice Technology illustrates the benefits: youtube.com/watch?v=U6XTdj0BSpg

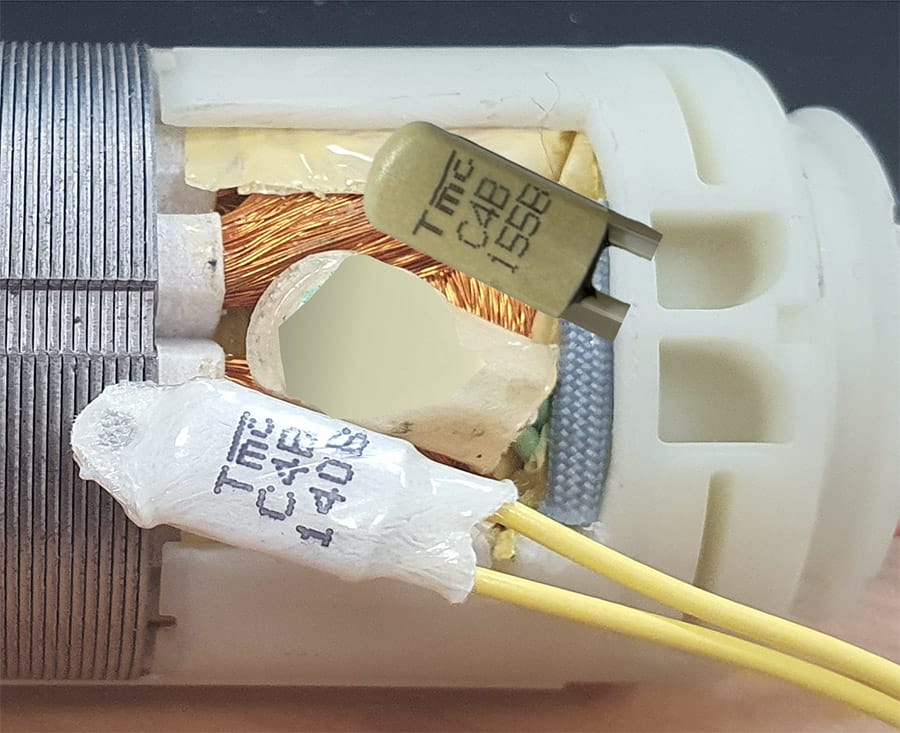

The world’s smallest bimetal switch

As small as possible and yet robust: our developers met this requirement for the new bimetal switch with a pressure-resistant, high-performance miniature switch.

Including its innovative insulation cap, this switch is currently the world’s smallest pressure-resistant bimetal switch available.

- High pressure resistance thanks to inner steel housing

- 3.5 kV dielectric strength of the insulation

- 100% consistent geometry

- No sharp edges

- 100% EU supply chain

Always in the perfect position

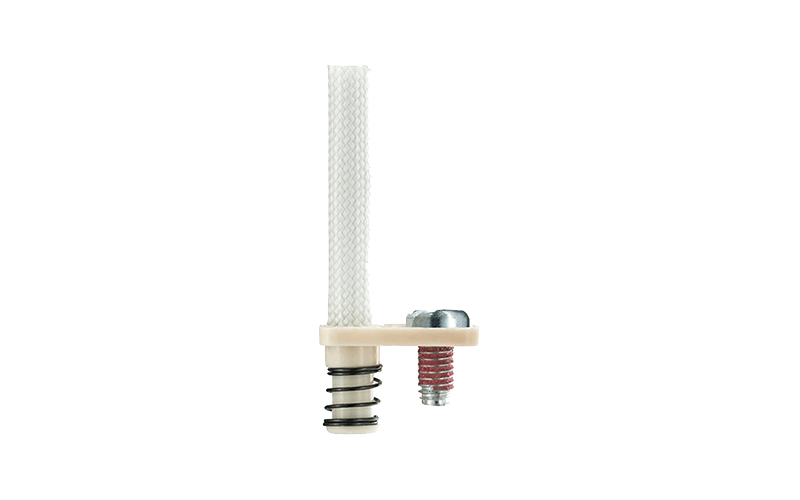

How can a Pt1000 sensor, designed for installation in different stator cast parts, always remain in the ideal position? Our answer: the “PI-Sensor”. The Pt1000 is encapsulated in a highly conductive plastic sleeve and, with the support of a spring, is reliably kept in the ideal position against the cast part.

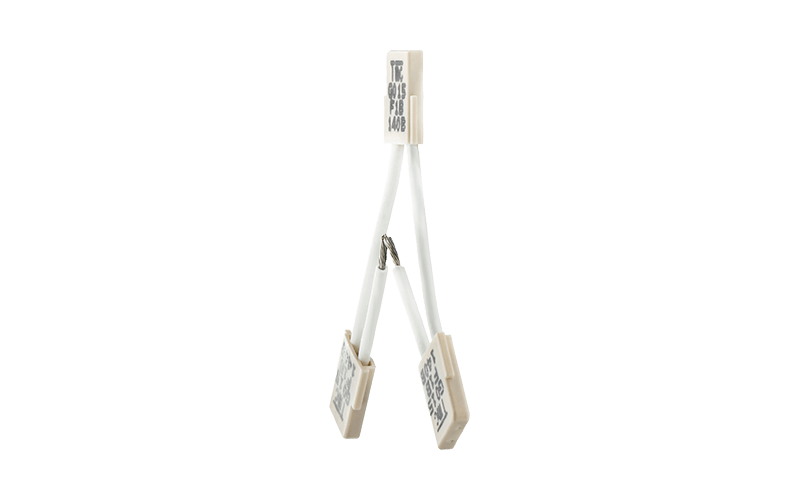

The world’s flattest bimetal switch

Especially in small electric engines with concentrated windings, every tenth of a millimeter counts. Our F-Switch, the flattest bimetal switch in the world, fits between all modern winding teeth.

Applications

Our solutions and products safeguard a vast variety of applications across industries worldwide. Whenever thermal safety is critical, thermal protection is essential. You will find TMC temperature sensors and bimetal switches in the following fields:

- Drive and control systems

- Heating and air conditioning

- Pumps

- Medical technology

- Laser applications

- E-mobility

- Lighting solutions

- Wind power

- … and many more!

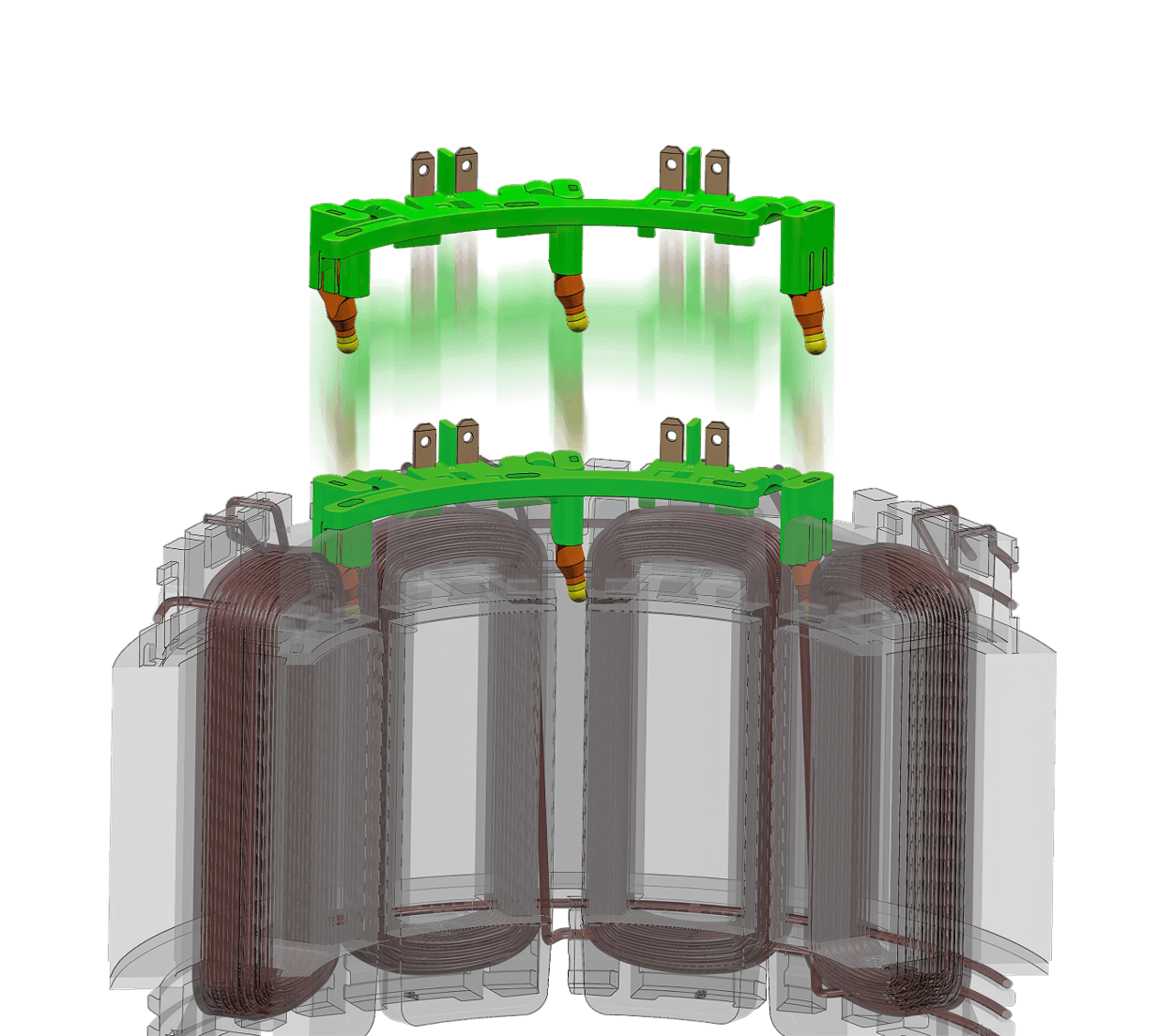

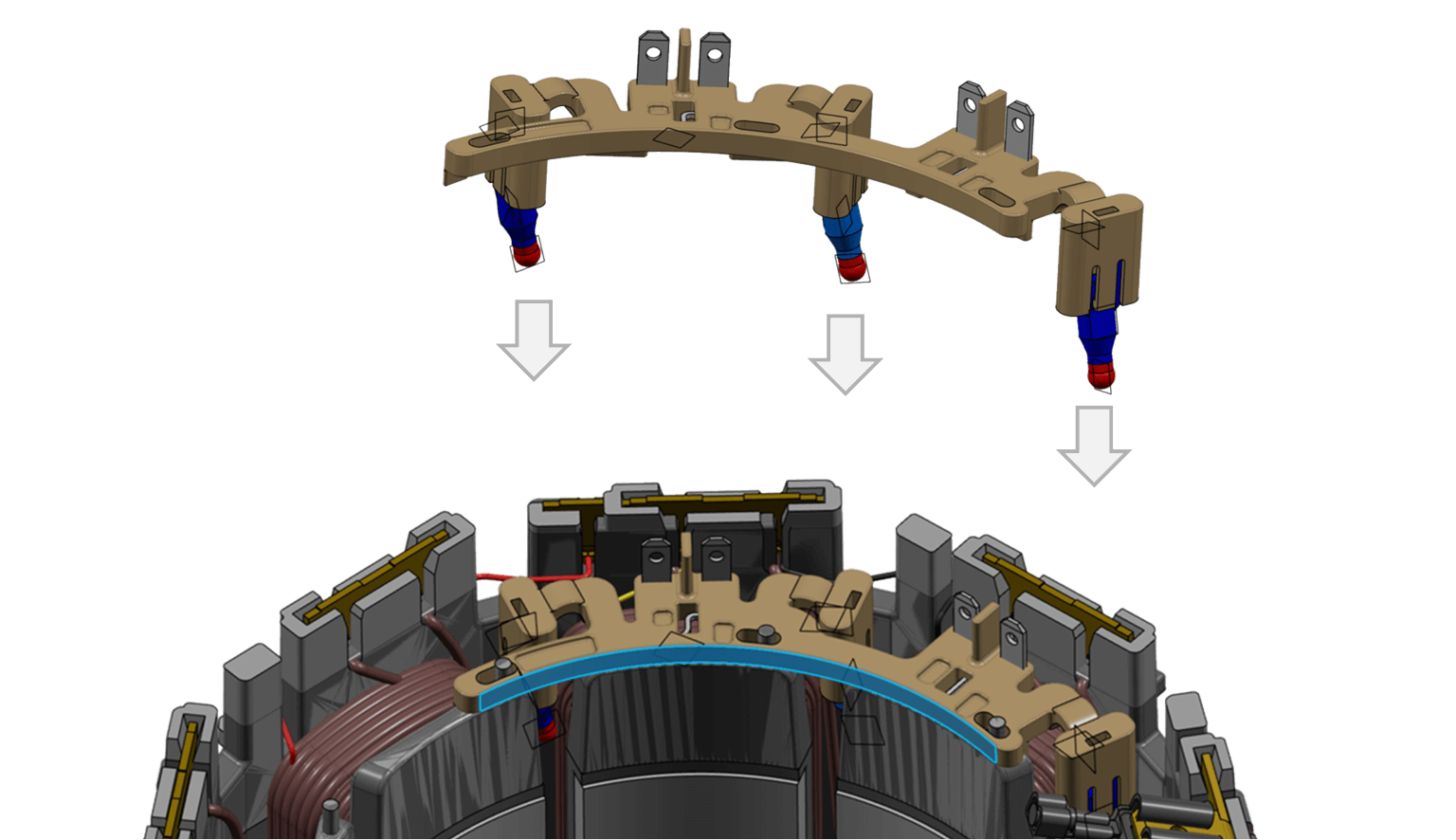

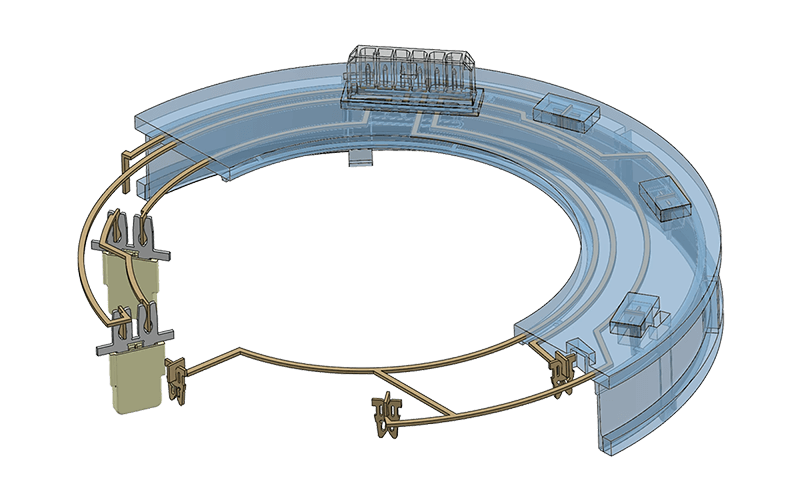

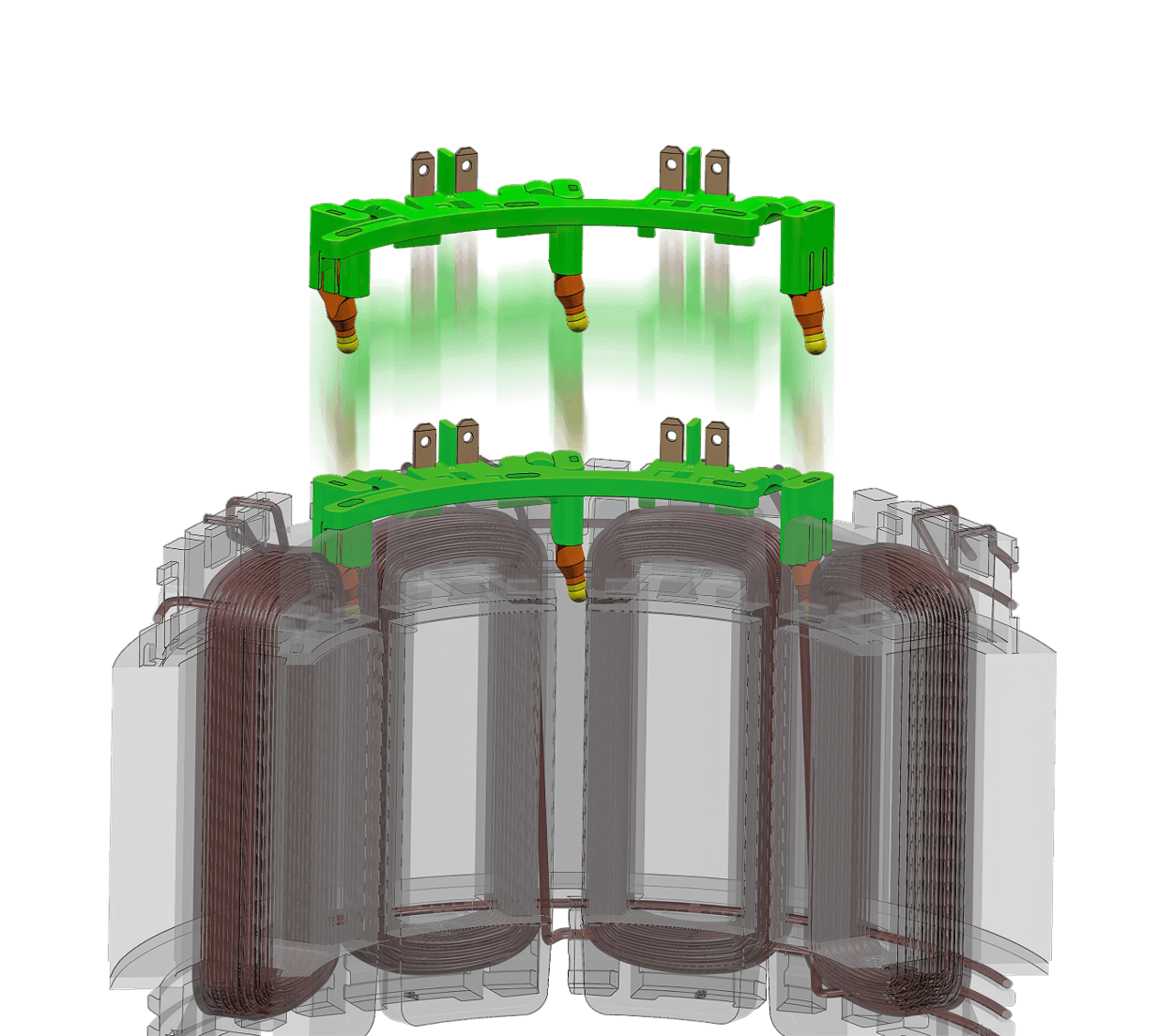

„Click & Play“

In cooperation with our sister company BGF Enztech GmbH, we create cost-efficient, tailor-made “Click & Play” solutions for you:

- Wire-free: Molded lead frame for reliable power supply, signal transmission and contacting

- Safe: Innovative insulation displacement connections, Press-Fit technology and more

- Flexible: All circuit options available in a single component (parallel or series, star or delta)

- Tailor-made: All sensor types (PTC, Pt1000/Pt100, NTC) and bimetal switches can be integrated flexibly and positioned variably – with just one “Click”.

- Savings: Substantial reductions in product costs, assembly costs and quality costs – often exceeding €3.00 per motor in assembly costs alone.

- Cost-efficient for volumes of 10,000 motors per year and above

SAVINGS EXAMPLE WITH “CLICK & PLAY”

- Production volume: 100,000 motors per year

- Assembly time before: 210 seconds per motor

- Assembly time after: 88 seconds per motor – assembly time reduced by 58%

- At an hourly rate of 98 EUR/hour: savings of more than 330k EUR per year, i.e. over 3.00 EUR per motor

“Click & Play” systems can be configured with:

- PTC

- Pt1000/Pt100

- NTC

- Bimetal switches

Click & Play use cases

SEGMENT: ELECTRIC ENGINE FOR DRIVE SYSTEMS

- Flexible sensor configuration: 3, 2, 1 or no bimetal F-switch (140°)

and/or 1 Pt1000 sensor - Star or delta connection – realized from a single tool

- Winding conductor contacting via insulation displacement connections (IDC),

Standard connector interface - SOP: Q4 2025 – pre-series: Q2 2025

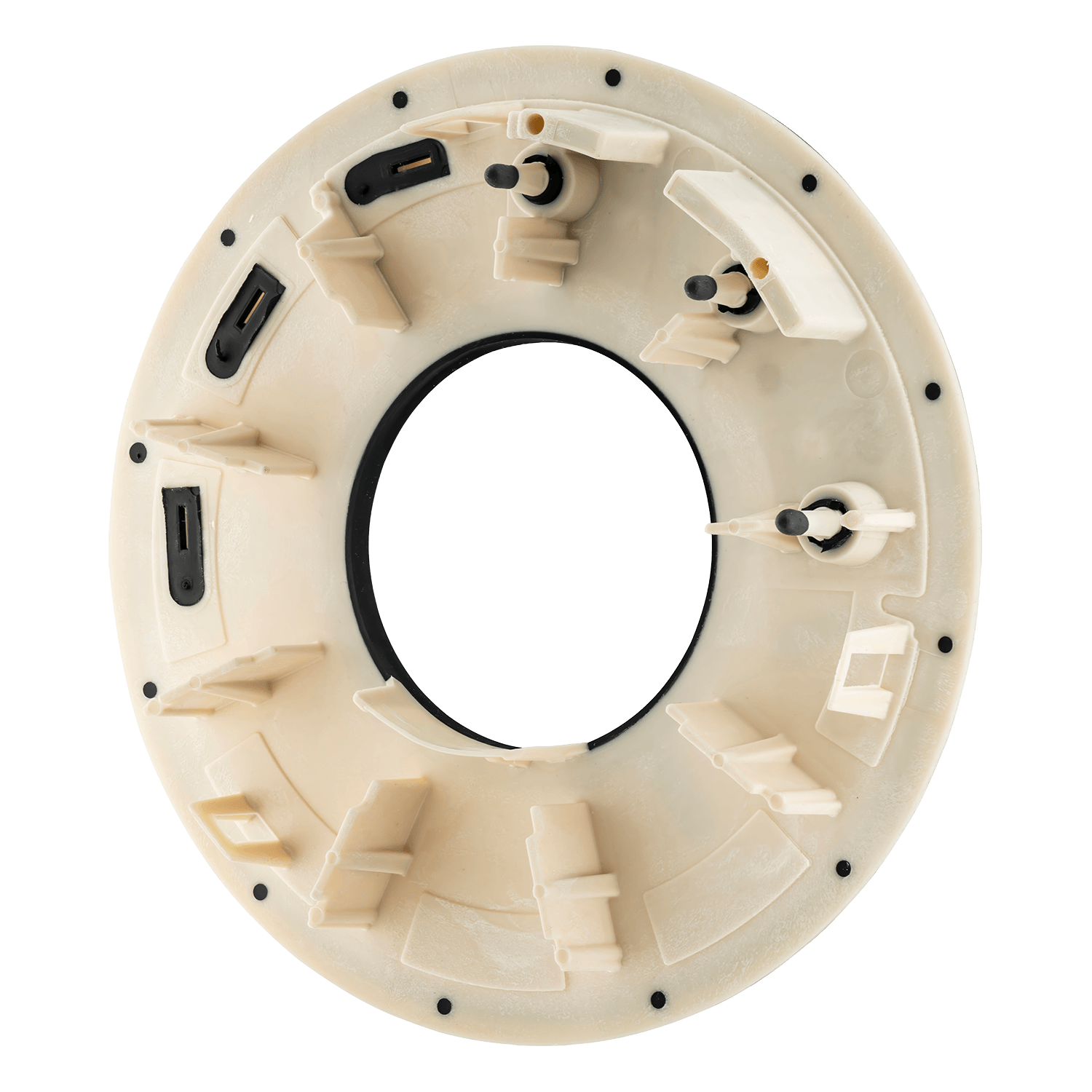

SEGMENT: ELECTRIC ENGINE FOR COOLING PUMP APPLICATIONS

- 3 PTC rockets (series connection)

and 3 Pt1000 sensors (parallel connection) - Parallel or series connection – realized from a single tool

- Flexible mounting with spring elements ensures constant thermal contact to the winding; secure connection via IDC

- SOP: Q1 2026 – pre-series: Q2 2025

Do you have questions about our “Click & Play” solutions – or are you looking for a customized solution?